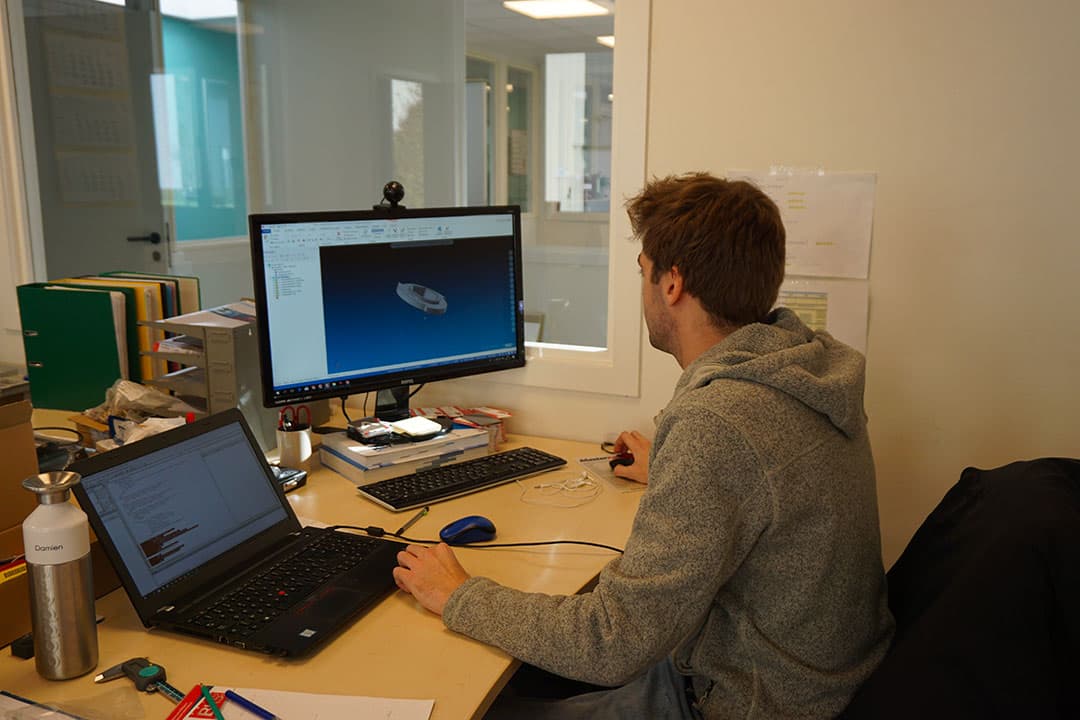

Let’s meet Damien, Engineering manager

With four production sites all over the world, BKS is your blade producer for various industries like Plastics, Recycling, Steel, Packaging and much more!

We have been established in 1983 and have continuously invested in our people and state of the art technology since then.

We are proud to own the most advanced software and production equipment and are keen to help you out with all your slitting and cutting challenges.

With this series of 10 interviews, we invite you to meet the people behind our blade manufacturing company. All of them play a key role in making our company unique.

Hi Damien, tell us about your job at BKS.

I’m engineering manager in the Production department. At BKS we produce parts from scratch from raw materials such as steel, stainless steel, aluminium, plastics etc. My job is to set up and monitor complete production processes.

On the basis of samples or customer specifications, I design and draw up the parts to be produced using computer-aided design software. Once the design is complete, I draw up a specific production schedule according to the different stages of the process: milling, turning, heat treatment, grinding, electro-erosion, etc. If necessary, I train the BKS operators on the different production machines. I then follow up by checking that each stage of production is running smoothly.

What qualities and skills do yo need to do your job?

I have to be versatile and organised to be able to move from one project to another. I also have to be creative and rigorous to achieve an optimal and fast production process. And of course, I have to be self-taught because working in the field is obviously always different from what you learn in training.

What do you like best about working at BKS?

First of all, I like the diversity of the tasks and the fact that I can manage an entire department and see it evolve over time. It allows me to deal with the different human and technical challenges that come my way.

Secondly, I find it interesting to start with a raw product and end with a ready-to-use part, going through all the production stages in our workshop. Especially since the company is not afraid to produce complex and technical parts for an international and demanding clientele.

Finally, working at BKS means working in a medium-sized company with a flat hierarchy and a very good working atmosphere. This is a considerable bonus!