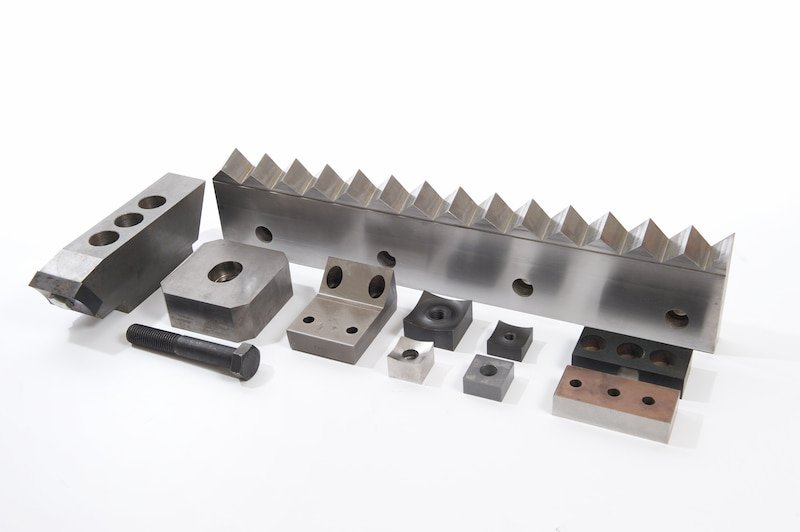

Wood chipper blades

At BKS, we assure the production and maintenance of wood chipper blades. Our team of experienced engineers guarantee a high quality and personalized production according to your requirements. In order to satisfy the requests of the professional businesses we work with, BKS exclusively uses high standard steel in its production process. We offer the production of different types of blades : the wood chipper blade, the circular saw blade and various kinds of hammers.

Firstly, the wood chipper blade is perfectly appropriate to transform wood into wood chips. Secondly, the circular saw blades for wood can be used for cutting any piece of wood to the right shape and length.

Last but not least, hammers are used to produce wood pellets that can be used in various heating systems.

These blades are made of chromium steel, sometimes even with a carbide inlay. They have varying measurements and hardnesses depending on your application.

Perks of a good maintenance

- Safety hazards are reduced

Well maintained blades prevent accident risks. Excessive vibrations and strains on wood chipper blades undermine them. Then, the tool is likely to cause accidents.

- Engine horsepower and diesel consumption are reduced

Maintaining the quality of a blade is recommended. It enables both to save fuel and to improve the functioning of the machine.

- Maintaining the quality of the machine

Low-quality chips, sawdust, or wood pieces are the results of a damaged machine. On the contrary, a properly maintained wood chipper blade ensures the quality of wood chips and the precision of cuts and angles.

- Saving time and money

A well-maintained blade is more efficient. As its quality is high, less fuel is required in the production process. Thus, it is less expensive and quicker to use it.

How do you maintain the blades?

Maintaining blades in good working order required to respect some conditions:

- Sharpening

Sharpening blades carefully and regularly in order to preserve its quality. - Replacing the blades when it is required

Part of maintenance includes replacing worn-out parts. Wood chipper blades that have outlived their lifespan should be replaced. - Store the blades in dry areas

Storing blades in a wet and moist environment exposes them to rust, which wears them out. A dry environment prevents rusting. - Tightening nuts and bolts holding the blades

Loose nuts and bolts cause safety hazards. The blades held by loose bolts and nuts could let go of the edge, causing damage. - To wrap it up

Circular saw blades for wood cutting and wood chipper blades request good maintenance. In order to preserve the quality of the products, investing in good maintenance is essential. To do so, BKS offers top-notch maintenance services to its clients.